LANGUAGE

LANGUAGE

Gearboxes, used in every corner of the industrial world from high-temperature and high-pressure mining to power generation, are facing the threat of increasing micro-pitting in their design and structure. Micro-pitting is a fatigue stress phenomenon on gear teeth, often attributed to changes in the quality of steel and the methods of surface treatment. In addition, the increase in temperatures resulting from reduced oil usage in the quest for higher power densities puts greater stress on the teeth, bearings, housing seals and other components of modern high-performance industrial gearboxes.

Taking these factors into account, lubricants must provide improved thermal stability, improved bearing protection, improved seal and internal coating compatibility and superior anti-micro-pitting performance. The most explicit reference to this requirement is the strict requirements of the Siemens MD specification for helical gears, bevel gears and planetary gears.

Siemens MD specification

The Siemens MD (Flanders) specification aims to ensure zero performance failures in Flanders gearboxes for heavy industrial applications. The specification focuses on material compatibility and performance against micro-pitting and scratches. Today, it requires the formulation of high-performance industrial gear oils as an integral part of the gearbox design. In addition to the requirements of DIN 51517-3 for lubricants, Siemens MD also requires the FVA 54 micro-pitting test, the dynamic foam test and the strict adherence to multiple protocols to ensure compatibility between internal coatings, elastomer seals and liquid seals.

Chemical additives that meet one aspect of the specification may adversely affect other aspects of performance, which has been a major problem in lubricant formulation. For example, it has been shown that a number of lubricants have qualified seal compatibility, but they will cause the coatings in Flanders gearboxes to bubble, while other lubricants that do not react with coatings are incompatible with ballistic seals. The Siemens MD specification has revised a number of performance requirements for coatings and ballistic seals. Therefore, there is a need for a new additive solution that can ensure the long-term integrity of the gearbox material while providing protection against micro-pitting.

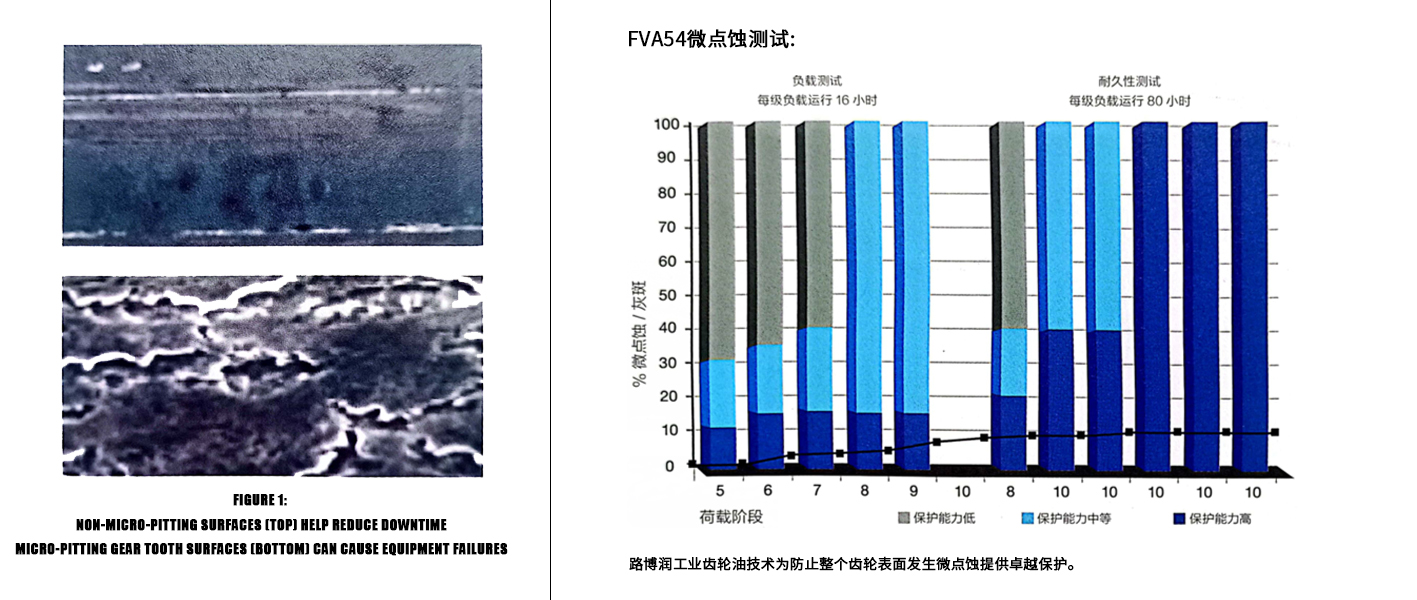

The consequences of micro-pitting

Micro-pitting is a form of surface fatigue. It is initially formed as tiny pits that are almost invisible to the naked eye (see Figure 1). They look like gray, dull areas, often called gray spots. Over time, micro-pitting may gradually weaken, or even disappear, without causing further fatigue. This is one possibility. Another possibility is that micro-pitting will further increase and deepen, causing noise and vibration. It will also affect the smooth meshing of the gear, or even continue to develop into pitting - causing more serious fatigue of the gear, resulting in operational disruptions and expensive maintenance costs.

Chemical breakthrough

By introducing a new industrial gear oil technology, Lubrizol has solved the dilemma of "seal and paint cannot both be", while providing excellent anti-micro-pitting performance and excellent bearing protection capabilities. Numerous laboratory tests have shown that this new technology can improve the following performance in class I, II and IV base oils:

While Siemens MD certification is limited to specific base oil formulations, Lubrizol's breakthrough technology is available not only as additive compounds but also as finished products. In addition, Lubrizol has developed a brand upgrade program to help lubricant distributors without the resources for Siemens MD-designated base oils obtain formal Siemens certification. The latest version of the 13th edition of the certification of finished products includes Lubrizol *FM2205 A to Lubrizol *FM2209 A, with ISO viscosity grades from 150 to 1,000.

Lubrizol's new line of industrial gear oils technology crosses the threshold of the Siemens MD specifications, eliminating the worry of micro-pitting and material incompatibility, thereby helping to reduce maintenance costs and prolong uptime.

Lubrizol's new line of industrial gear oils technology ensures:

● Extended life of gears and bearings in closed gear drives operating under extreme loads, speeds and temperatures

● Excellent oxidation resistance at high temperatures, thereby extending the life of the lubricant and extending the oil change period

● Smooth operation in high and low temperature environments, reliable performance throughout the year

● Excellent corrosion resistance and excellent emulsification resistance, ensuring trouble-free operation in applications where water contamination is unavoidable

● Reduced filter clogging, thereby reducing the number of filter replacements

●Reliable compatibility with ferrous and nonferrous metallurgy, internal coatings and current liquid sealants and elastomers used in high performance gearboxes

The advantages of Lubrizol technology

To obtain Siemens MD certification, several conditions need to be met. Testing is expensive and time-consuming, and some tests can only be performed in a few approved external laboratories. Faced with these practical problems, lubricant manufacturers may prefer to purchase finished product lubricants that have been tested, certified and certified by the original equipment manufacturer.Source: Lubrizol 《液界》 Tim Cooper, Global Product Manager, Industrial Oils

CONTINUE READING:

MerRIND® SGL Series High Performance Industrial Robot Gear Oil

Designed for harsh operating environments of industrial robot gearing applications

MerRIND® SGL series is specially developed for the gear lubrication of industrial robot reducer, which has high bearing capacity, advanced micro-pitting protection, good filtration performance, good bearing lubricity and long life performance. This gear oil is specially designed to reduce friction loss and energy consumption (compared with traditional lubricating oil). The product is formulated with international high-standard base oil and excellent additives, which has excellent extreme pressure resistance and anti-wear protection ability, extremely high thermal stability, oxidation stability and rust prevention and corrosion prevention ability. It does not affect the ordinary sealing materials or coatings in gear bushes. Outstanding characteristics can be used for a long time under extreme climate conditions.

Wide range of applications, making business operations smoother

MerRIND® SGL series of high performance industrial robot gear oil, can provide excellent wear protection for the reducer, thus providing long-term oxidation stability and good corrosion protection performance. Its application areas include industrial robots, rail transit and mechanical engineering, etc. used in various types of gear industry.

● All kinds of normal gear under various difficult load conditions.

● Bevel gear units, including such units with large offsets (hypoid) and alternating heavy loads.

● All kinds of high and low temperature rolling bearings with heavy load.

● Can be used in a very wide temperature range (no need to preheat in winter).

● Soak lubrication at high speeds, as well as oil injection and oil mist lubrication. Does not have any effect on the ordinary sealing material or paint in the gear bushing. Filtration (mechanical) does not cause any loss of additives.

●The friction coefficient is low, so it is not suitable for synchronous gear and limiting slip differential device.

High-performance advantages

● Saving energy costs

Unique high performance base oils and additives give the lubricant excellent traction properties. Lower internal fluid friction helps to reduce oil temperature, thereby showing huge energy saving potential.

● Advanced anti-micro pitting protection

MerRIND® SGL series is a synthetic gear oil with high viscosity index and low traction coefficient, with a balanced formula, taking into account the needs of various performance, can effectively control micro pitting.

● Extend the service life of equipment

High load capacity and corrosion protection combined with balanced anti-foam and air release properties can further reduce equipment failures and demonstrate the potential to improve operational productivity.

● Reduce inventory and administrative costs

MerRIND® SGL series gear oils have a wide range of applications, helping to reduce inventory and management costs.

Environment, Health and Safety

This product is accompanied by Material Safety Data Sheet (MSDS) and User Safety Guide. Users should use and discharge the product according to the prescribed steps and in accordance with relevant laws and regulations.

Currently, the challenge of global climate change is intensi...

MerRIND ® The Lean Lubrication brand was established in ...

In the long course of human civilization's evolution, we...

In the long river of human history, new technologies hav...

Hidden Champion "is a concept proposed by German busines...

On July 25, 2025, the Rhine River is rippling with blue ...

On July 12, 2025, the 2025 City Trip · Shanghai S...

MerRIND ® Lean Lubrication takes great pride in part...

Folding phone development trend: With its innovativ...

In today's world, technological progress and innovation ...