LANGUAGE

LANGUAGE

In today's world, technological progress and innovation have become the core driving force for the sustainable development of the manufacturing industry. As an important pillar of the global economy, manufacturing plays a crucial role in adopting new technologies, improving production efficiency, reducing costs, and meeting constantly changing market demands. Under the challenges of global climate change and sustainable development, the manufacturing industry must further innovate to achieve the future goal of zero carbon emissions. Technological innovation is crucial in this transformation, as it not only helps companies improve production efficiency and product quality, but also effectively reduces energy consumption and waste emissions, thereby driving the entire industry towards a greener and more sustainable direction.

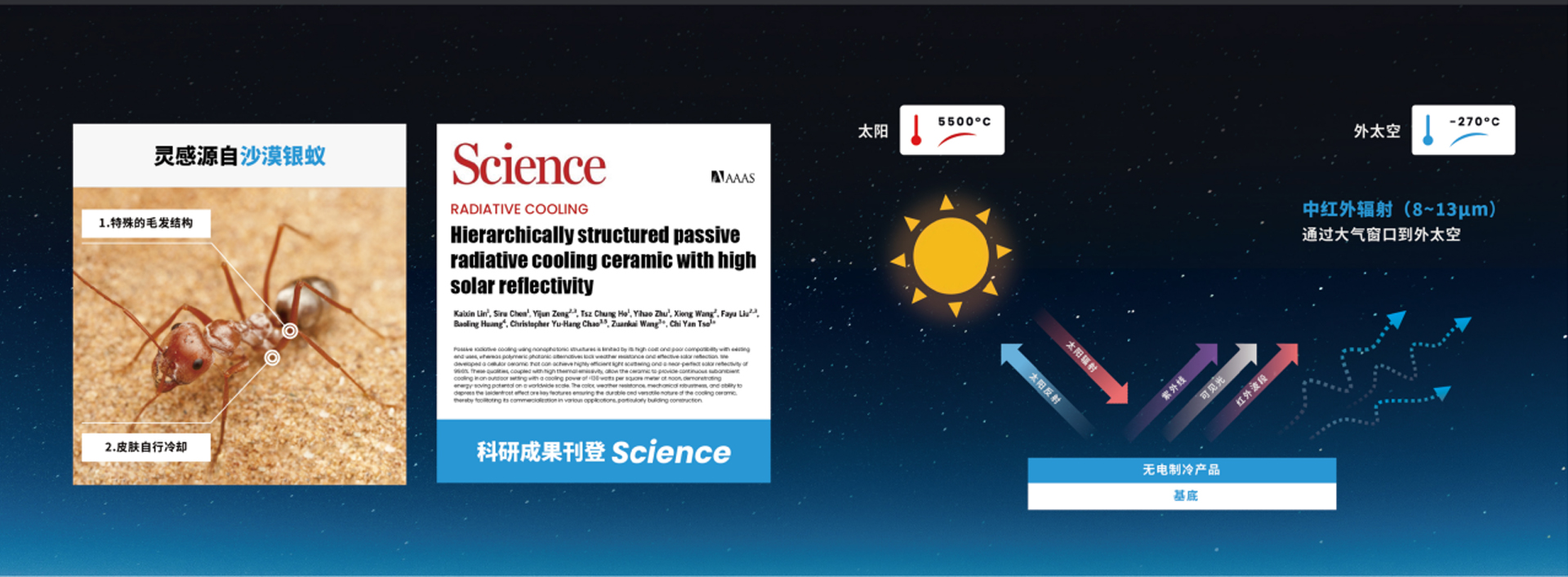

Emerging technologies refer to those technologies that have the potential to have transformative effects, are rapidly developing and gradually being applied in various industries. These technologies typically represent the forefront of innovation, providing breakthrough solutions that drive sustainable development of society, economy, and environment. Passive radiation refrigeration technology, as a green, environmentally friendly, and zero energy consuming refrigeration technology, is an emerging technology that has received much attention in recent years. It has a wide range of application fields, covering multiple areas from outdoor facilities to buildings, and has broad application prospects. The technical research and development difficulty of radiation refrigeration materials is to balance refrigeration efficiency and practicality. The effectiveness of radiative cooling depends on two optical properties of the material surface: one is the reflectivity of the solar band, which determines the ability to block solar thermal absorption; Another factor is the emissivity of the mid infrared band, which determines the material's ability to dissipate heat through the atmosphere and into outer space. The i2Cool research team, originating from the School of Energy and Environment at City University of Hong Kong, analyzed the impact of material solar reflectance (0.25-2.5 microns) and cooling power on mid infrared emissivity (8-13 microns). Research has shown that the increase in cooling power obtained by increasing the reflectivity of the solar band is much greater than the increase in mid infrared emissivity, which has become a breakthrough point in this study and provides new possibilities for achieving more efficient and environmentally friendly cooling technologies.

As a typical project of industry university research implementation in Hong Kong, i2Cool's technology source comes from Professor Cao Zhiyin's team. As one of the top 2% scientists in the world, he has been focusing on the research of passive radiation cooling technology for seven years, aiming to solve the problem of building space energy consumption. The technological feature of i2Cool lies in its breakthrough principle - the deep fusion of solar reflection and mid infrared radiation, which are the key to achieving the dual effect of "insulation+automatic cooling". By reflecting sunlight, it can effectively reduce the absorption of solar heat; By emitting mid infrared radiation, internal heat is released into outer space, reducing heat accumulation and making the surface temperature lower than the ambient temperature, thereby lowering indoor temperature and reducing the load on the refrigeration system. Taking the non electric cooling coating as an example, through material optimization, i2Cool's core product, the non electric cooling coating, achieves 95% high solar reflectivity and mid infrared emissivity while still demonstrating excellent material stability, breaking through the technical bottleneck of traditional insulation coatings that are difficult to achieve reflectivity of over 90%. During the hot summer with strong sunlight, non electric cooling can reduce the temperature of the building surface by up to 42 ℃ through coating, making it durable and significantly improving energy efficiency.

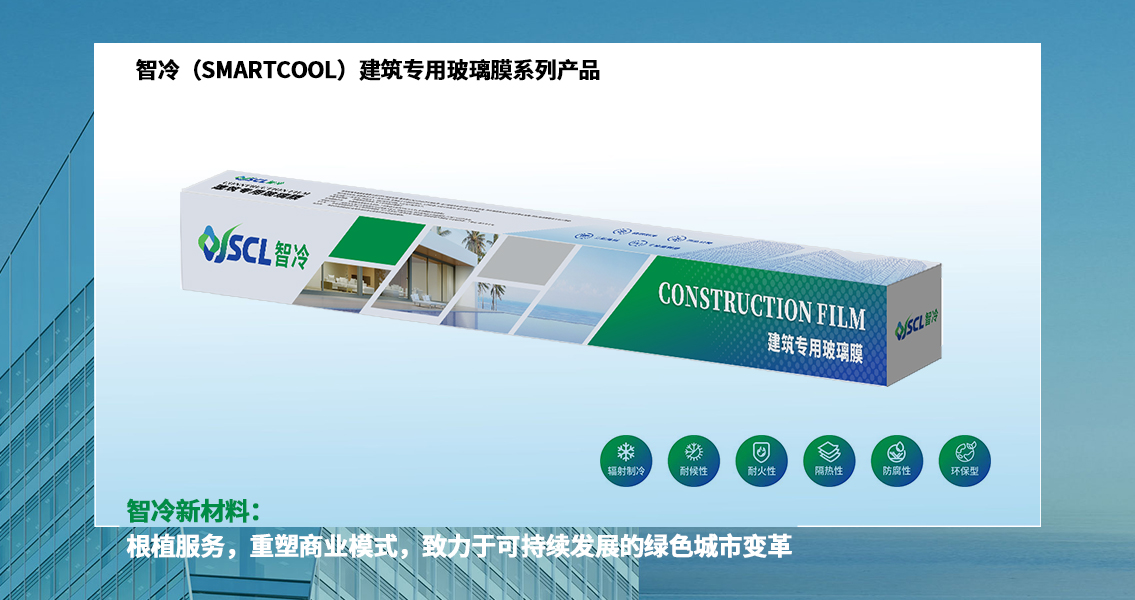

The i2Cool non electric cooling coating iPain only needs to be applied to the surface of buildings or industrial equipment, without the need for external power or refrigerant, to suppress heat absorption and promote heat dissipation, achieving zero energy cooling. The i2Cool non electric cooling film iFilm is suitable for both inside and outside glass applications, effectively isolating insulation gain and reducing indoor temperature. It balances high transparency and high insulation, significantly reducing the demand for air conditioning cooling and saving energy. It can be widely used in fields such as construction, chemical industry, power communication, new energy, logistics, grain storage, and photovoltaics.

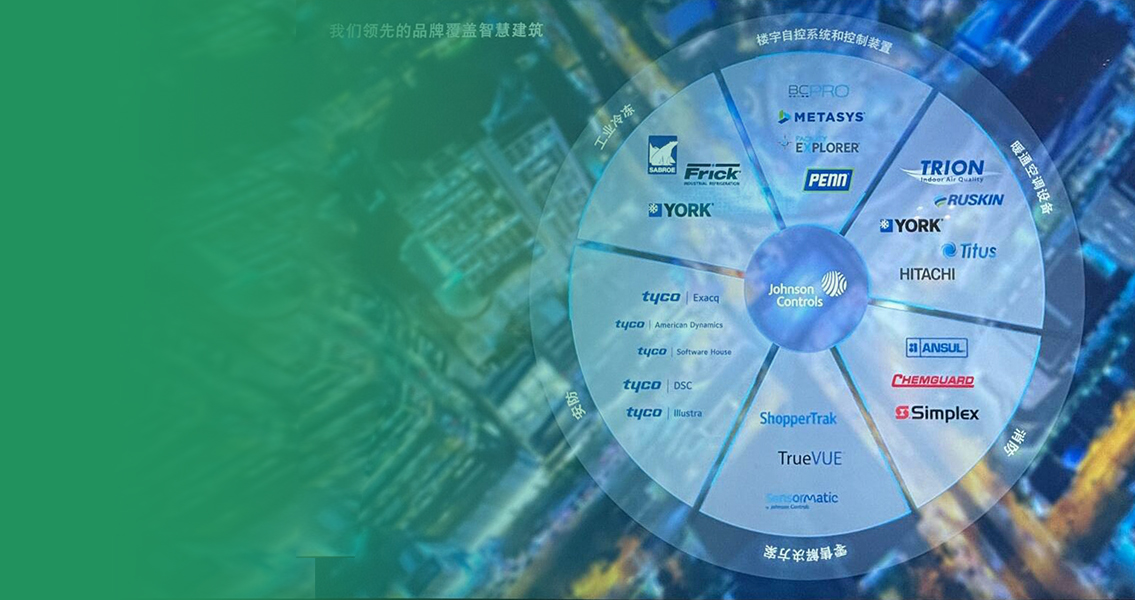

At present, i2Cool has established cooperative relationships with over 100 government agencies, developers, and industry leaders worldwide, and has implemented over 200 application projects. As a technology leader in the industry, i2Cool's electric cooling solution has been implemented in several iconic buildings around the world, including the Dubai Mall, one of the world's top shopping and entertainment destinations, the Hong Kong Coliseum, one of Asia's most popular entertainment venues, and the Times Square, a commercial building in Hong Kong.

Currently, the challenge of global climate change is intensi...

MerRIND ® The Lean Lubrication brand was established in ...

In the long course of human civilization's evolution, we...

In the long river of human history, new technologies hav...

Hidden Champion "is a concept proposed by German busines...

On July 25, 2025, the Rhine River is rippling with blue ...

On July 12, 2025, the 2025 City Trip · Shanghai S...

MerRIND ® Lean Lubrication takes great pride in part...

Folding phone development trend: With its innovativ...

In today's world, technological progress and innovation ...