LANGUAGE

LANGUAGE

Lubrication management is an important part of equipment management, and equipment safety is highly correlated with lubrication safety. Lean lubrication management is a method of optimizing the whole process of lubricating oil by using scientific means, including reasonable selection of oil, oil status monitoring, oil pollution prevention and control, oil field management (storage, filling, etc.), oil recycling management, etc. Lean lubrication management has important practical significance for promoting green manufacturing and sustainable development of enterprises, improving the level of lubrication management of enterprises, maintaining equipment precision, reducing equipment failure rate and reducing the total cost of equipment lubrication maintenance.

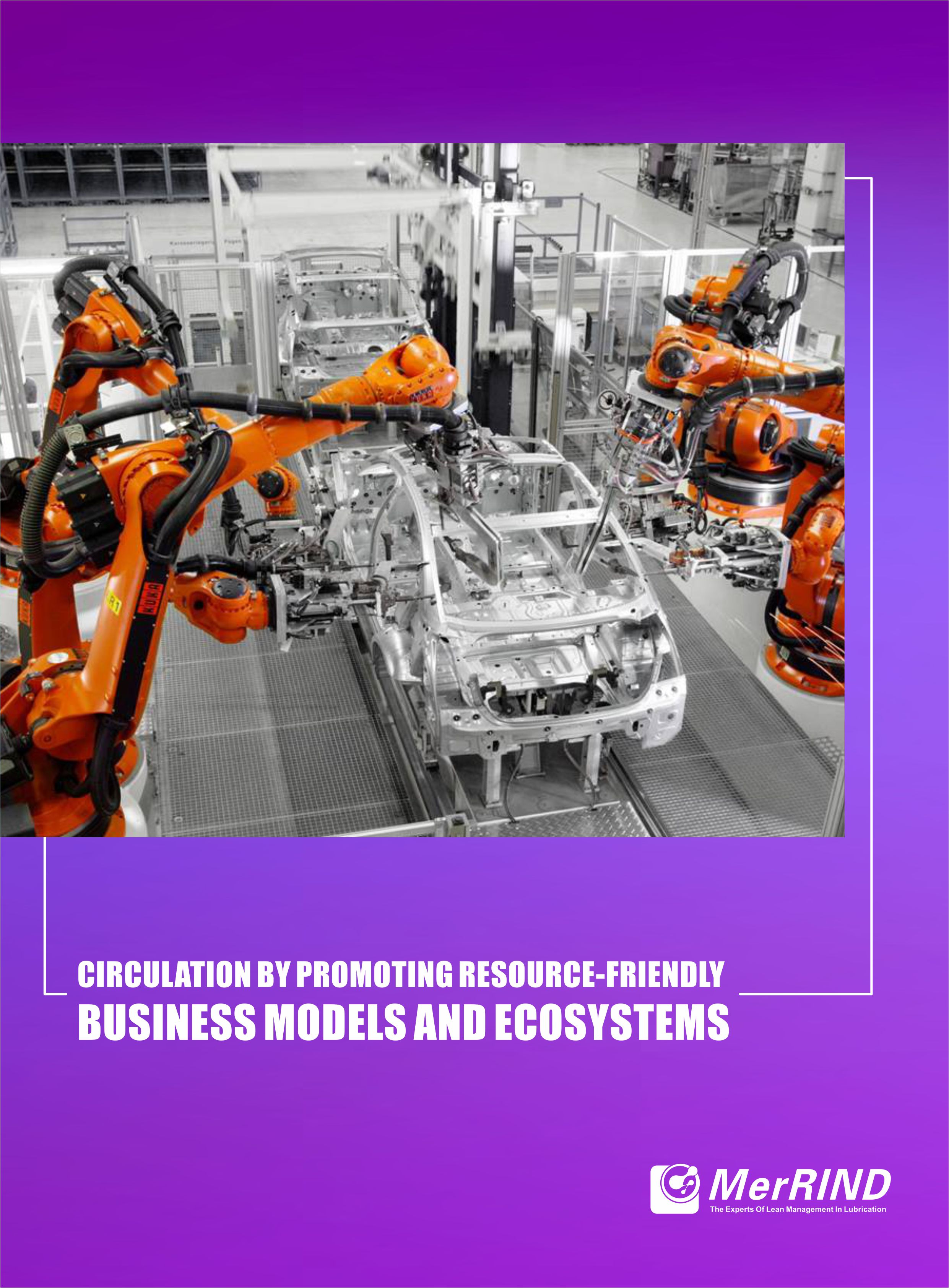

Optimization of robot grease selection is the basis of lean lubrication management of equipment. The merger and optimization of robot equipment lubricating oil is to reduce the types of grease used for inventory management, and to reduce the chance of misuse of grease. Finally, scientific substitution reduces the cost of lubrication oil for enterprises. The principle of oil selection for robot equipment is suitable, accurate and matching. Not the highest quality as the selection standard, but the equipment personnel on the basis of enterprise robot equipment operation, process, status, environmental conditions, load, speed, temperature, friction pair types and other systems master, scientific, data to determine the type of lubricant, viscosity level, quality level, in the guarantee of the use of the right oil equipment on the basis of reducing equipment maintenance costs, prolong the life of the core components of the equipment. The optimization of grease is an important measure to effectively improve the efficiency of enterprise lubrication.

MerRIND® brand was founded in 2008, MerRIND® long-term focus on high performance industrial robot lean lubrication management field, with long-term practice and knowledge engineering in the industry, to provide innovative products and professional technology, to help partners improve their competitiveness in the market. In the field of industrial robot lubrication, based on data and engineering, after a long period of practice, launched a fully synthetic, high performance, lean optimization of the Murray ® grease bag products, meet the demanding lubrication requirements of industrial robot equipment, to robot as a unit, humanized design packaging, accurate to the joint shaft of the Murray ® industrial robot lean grease bag, improve the maintenance efficiency of robot engineers, reduce the pollution of the environment in the process of equipment maintenance, reduce the risk of direct contact between the field maintenance personnel and lubricating oil, excellent quality, lean optimization of the special grease bag products not only meet the technical requirements of the equipment, but also help enterprises reduce the variety of oil and inventory, directly reduce the procurement cost and management cost, eliminate unnecessary waste, but also avoid the possibility of misuse of lubricating grease.

Currently, the challenge of global climate change is intensi...

MerRIND ® The Lean Lubrication brand was established in ...

In the long course of human civilization's evolution, we...

In the long river of human history, new technologies hav...

Hidden Champion "is a concept proposed by German busines...

On July 25, 2025, the Rhine River is rippling with blue ...

On July 12, 2025, the 2025 City Trip · Shanghai S...

MerRIND ® Lean Lubrication takes great pride in part...

Folding phone development trend: With its innovativ...

In today's world, technological progress and innovation ...